If you’re comparing CNC machines, you’ll see plenty of specs thrown around—horsepower, travel size, rigidity, controller voltage. One feature that often gets overlooked, but has a huge impact on real-world performance, is the motor encoder.

Encoders

Encoders are one of those behind-the-scenes components that quietly make a CNC machine more accurate, more reliable, and more forgiving when things don’t go perfectly—which, in machining, they rarely do.

Let’s break down what motor encoders are, what they do, and why they make a CNC better.

What Is a Motor Encoder?

A motor encoder is a sensor attached to a CNC motor that continuously reports the motor’s position, speed, and direction back to the controller.

Think of it as real-time feedback.

Without an encoder, the controller simply assumes the motor moved where it was told.

With an encoder, the controller knows exactly what happened—and can correct mistakes instantly.

Open-Loop vs Closed-Loop CNC Motion

Open-Loop (No Encoder)

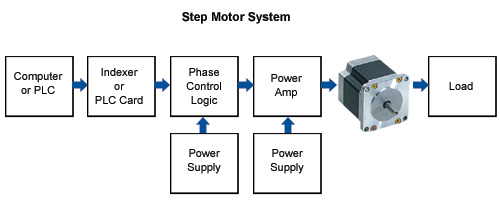

Most basic CNC machines use open-loop stepper motors:

-

The controller sends steps

-

The motor moves (hopefully)

-

No confirmation is sent back

If the motor:

-

Misses steps

-

Binds under load

-

Loses torque during aggressive cuts

👉 The machine doesn’t know—and your part can be ruined without warning.

Closed-Loop (With Encoder)

Encoders create a closed-loop system:

-

The controller commands motion

-

The encoder verifies the movement

-

Errors are corrected instantly

If the motor falls behind, the system compensates—or stops and alerts the user.

Why Encoders Make a CNC Better

1. More Accuracy Where It Counts

Encoders ensure the cutter is exactly where the software thinks it is—especially important for:

-

Fine detail work

-

Joinery

-

Inlays

-

Multi-pass machining

Instead of hoping position is correct, the machine actively verifies it.

2. No More Lost Steps

Lost steps are one of the most common causes of ruined CNC jobs.

Encoders:

-

Detect missed steps immediately

-

Correct position in real time

-

Stop and alert the user when hard stops are detected

-

Prevent cumulative errors that show up late in a job

This is especially valuable on:

-

Long runs

-

Heavier cuts

-

Harder materials

3. Higher Reliability Under Load

Real-world CNC work isn’t always gentle:

-

Knots in wood

-

Dense hardwoods

-

Tool wear

-

Minor workholding issues

Encoders help the CNC handle load changes without drifting off position, maintaining accuracy even when conditions aren’t ideal.

4. Cleaner Cuts & Better Surface Finish

When motion stays accurate:

-

Toolpaths stay true

-

Corners stay sharp

-

Surfaces come out smoother

That means:

-

Less sanding

-

Less rework

-

More consistent results from part to part

5. Confidence for the Operator

One of the biggest benefits isn’t mechanical—it’s psychological.

Encoders give users:

-

Confidence to run longer jobs

-

Confidence to cut more aggressively

-

Confidence that the machine will tell you if something goes wrong

That matters whether you’re a hobbyist or running a small production shop.

Are Encoders Only for Industrial CNC Machines?

Not anymore.

Encoders were once reserved for large industrial machines due to cost and complexity. Today, they’re increasingly found on high-quality small-format CNC machines designed for serious users who want:

-

Industrial-style reliability

-

Better repeatability

-

Fewer failed jobs

This is one of the clearest indicators that a CNC is engineered for real machining, not just light hobby use.

When Do Encoders Matter Most?

Encoders make the biggest difference when:

-

Cutting hardwoods or composites

-

Running longer programs

-

Using heavier spindles or tooling

-

Doing production or repeat work

-

Accuracy and consistency matter more than speed alone

If you’ve ever finished a job only to realize something shifted halfway through—encoders are designed to prevent exactly that.

How Next Wave’s Closed-Loop Encoder System Is Different

Many encoder systems only monitor individual motor movement. Next Wave’s closed-loop system works in coordination with the controller, unlocking additional functionality:

-

Motor positions are monitored and controlled continuously

-

Small position errors are corrected automatically

-

When errors exceed safe limits, the machine stops and alerts the user

-

Hard stops are detected and communicated to the controller

-

The controller updates its internal position data using actual motor positions, keeping on-screen X, Y, and Z coordinates aligned with the real machine

After any hard-stop incident, it is still recommended that the user re-home the machine. However, depending on project criticality, it is possible to continue machining using skip-line recovery and speed-change functions built into the 10.1″ pendant—often with excellent results.

Final Thoughts

Motor encoders don’t make flashy headlines, but they fundamentally change how a CNC machine behaves.

They turn motion from assumed to verified, from hopeful to precise.

If accuracy, reliability, and confidence matter in your CNC work, encoders aren’t just a nice feature—they’re a smart investment.

All HD6 PRO series machines feature encoded motors.

👉 Shop HD6 PRO Series Now