Tips for improving your cuts with your CNC

Choose the Right Bit for the Job Not all bits are created equal. Use bits specifically designed for your material—downcut bits for clean top edges on plywood, upcut bits for efficient chip clearing, and compression bits for minimizing tear-out on both edges of materials. Use the Optimal Feed Rate and Speed Matching the feed rate […]

More – CNC Woodworking Safety Tips

Essential CNC Woodworking Safety Tips for Every Maker Wear Appropriate Personal Protective Equipment (PPE) Eye Protection: CNC machines can throw small debris, and it’s crucial to protect your eyes from flying wood chips and dust. Hearing Protection: The noise from CNC routers can be loud and prolonged exposure may damage your hearing. Invest in quality […]

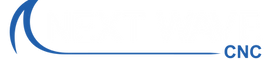

Small Vacuum Tables for CNC

Small Vacuum Tables for CNC: Optimizing Your Setup for Precision and Efficiency Small vacuum tables have become essential for CNC owners who need reliable and efficient methods for securely holding materials during machining. These tables ensure that materials don’t shift, delivering cleaner cuts and better overall product quality. When considering a vacuum table setup for […]

CNC Machining for Beginners: Getting Started with Your First Machine

Welcome to the exciting world of CNC machining! Whether you’re intrigued by the precision of automated machining or have aspirations of creating intricate designs, embarking on this journey can be both rewarding and overwhelming. In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, […]

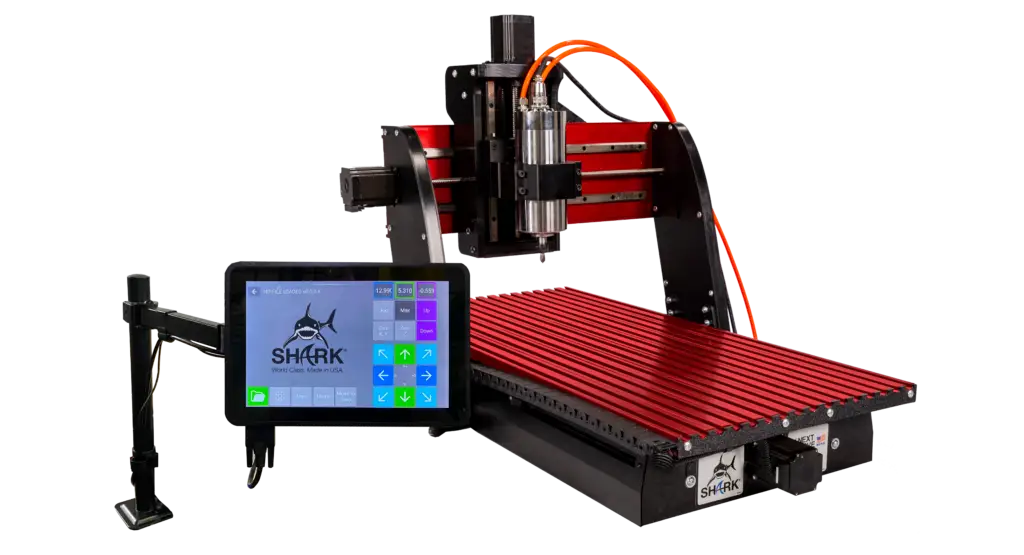

CNC SHARK MAINTENANCE TIPS

Periodic maintenance and lubrication keeps your SHARK CNC running efficiently and smoothly. If the Pendant buttons stop responding correctly, clean around the screen with a piece of paper. Use a dry lubricant for the rails, round bars, and leadscrews. Dry lubricant doesn’t attract dust. Purchase Dupont Silicon Teflon at your local Next Wave CNC retailer or online at: NextwaveCNC.com/shop. You will find similar dry […]

Don’t be limited by the Size of your CNC

Are you feeling restricted by the size of your CNC machine? If so, it’s time to consider an upgrade to VCarve Pro. With its innovative tiling function, VCarve Pro empowers users to create projects that extend beyond their CNC machine’s bed surface. This feature not only maximizes the capabilities of your equipment, but it also […]

Why Upgrade your Pendant?

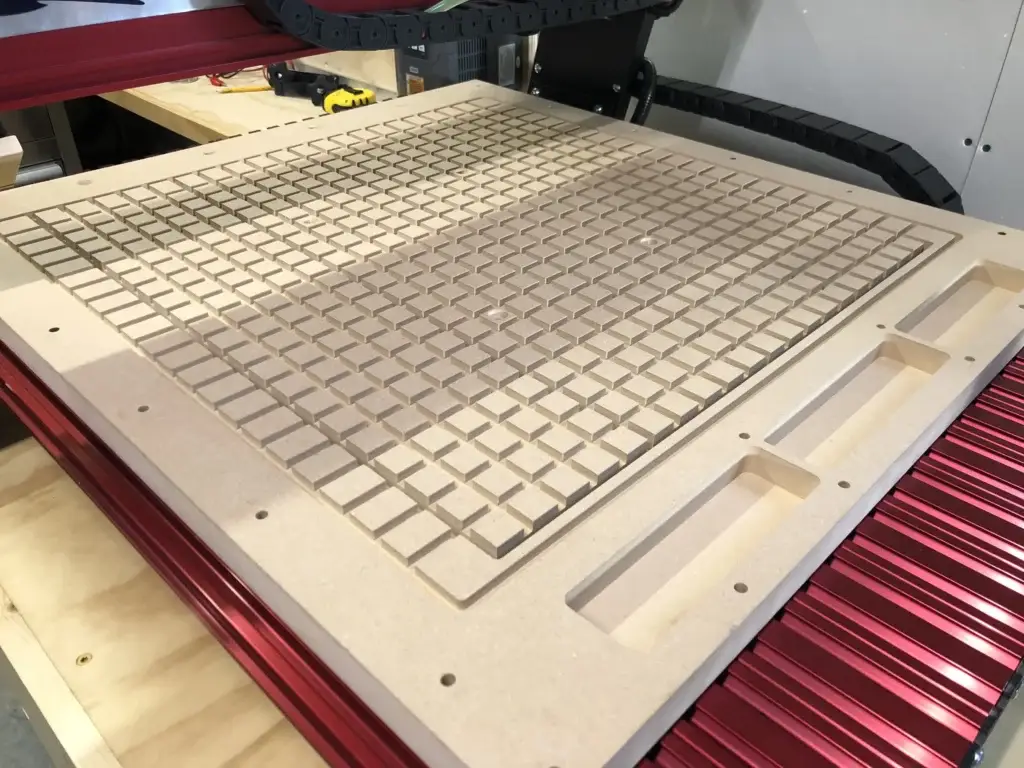

Upgrade Your Shark Pendant: Introducing the 10.1″ Touch Screen Display Are you ready to elevate your CNC machine experience? The new 10.1″ Touch Screen Display for your Shark Pendant is here to transform the way you work with your CNC equipment. Compatible with a vast array of CNC machines, including: All models of CNC Shark […]

4 Tips for Selling Your CNC-Made Products on Etsy

Selling your CNC-made products on Etsy can be a profitable and rewarding experience. The popular online marketplace allows crafters to easily reach a wide audience and showcase their unique creations. Ensure your success with our expert tips for selling your CNC-made products on Etsy. Decide on a Target Market Identifying your target market helps you determine […]

5 Tips for Tight-Tolerance CNC Machining

Many woodworkers use CNC machines to create unique and intricate pieces that would be hard or impossible to complete by hand. When using this tool, understanding the importance of maintaining a tight tolerance is crucial to producing high-quality products. Tight tolerance refers to the degree of accuracy and precision in the dimensions of a piece. […]

Z Zero – Top of the Material or Bed Surface?

Far and away setting the Z zero on the surface of your material is the most common, but occasionally it may make sense to use the top of the bed as a reference point. Here are a few reasons you might choose to do that. Material Thickness Consistency: Setting the Z zero at the machine […]

Essential Safety Tips for CNC Machine Hobbyists

CNC machines are incredible tools that allow woodworkers to create intricate designs in every project they create. As advanced as these machines are, users should always take precautions to remain safe during operation. As industry experts, we’ve compiled five essential safety tips for CNC machine hobbyists so that you can enjoy your pastime. Understand How […]

4 Things To Consider Before Buying a CNC Machine.

Having top-quality tools is essential for professional and hobbyist woodworkers, as it allows them to create works of art. You could buy a computer numerical control (CNC) machine to increase the precision of your work. A CNC machine communicates with a computer to create designs. Since it’s an expensive purchase, we’ll share four things to consider […]

Exploring Three Common CNC Project Materials

Computer Numerical Control (CNC) technology has transformed the woodworking and DIY industry for everyone from professionals to hobbyists. These machines allow individuals to create precise, detailed designs on various materials, including aluminum, wood, and plastic. Explore the common CNC project materials so that you know what to buy for your next project. Aluminum: The Lightweight […]

Enhancing Precision and Reliability: The Advantages of Ultra Screws in Small Format CNC Machines

In the realm of small-format CNC machines, the quest for precision has traditionally led to the use of ball screws. However, a disruptive force is emerging with the rise of lead screws, challenging the conventional belief that ball screws are the undisputed kings of accuracy. Drawing inspiration from the efficiency of 3D printers, the advantages […]

5 Must-Have Accessories for Your Hobby CNC Setup

Venturing into the use of computer numerical control (CNC) machines is an exciting journey as you craft your projects and bring your ideas to life. With the right tools and knowledge, you can turn a block of wood into a complex and intricate design within the comfort of your own home. To help ensure you […]