Product Details

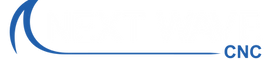

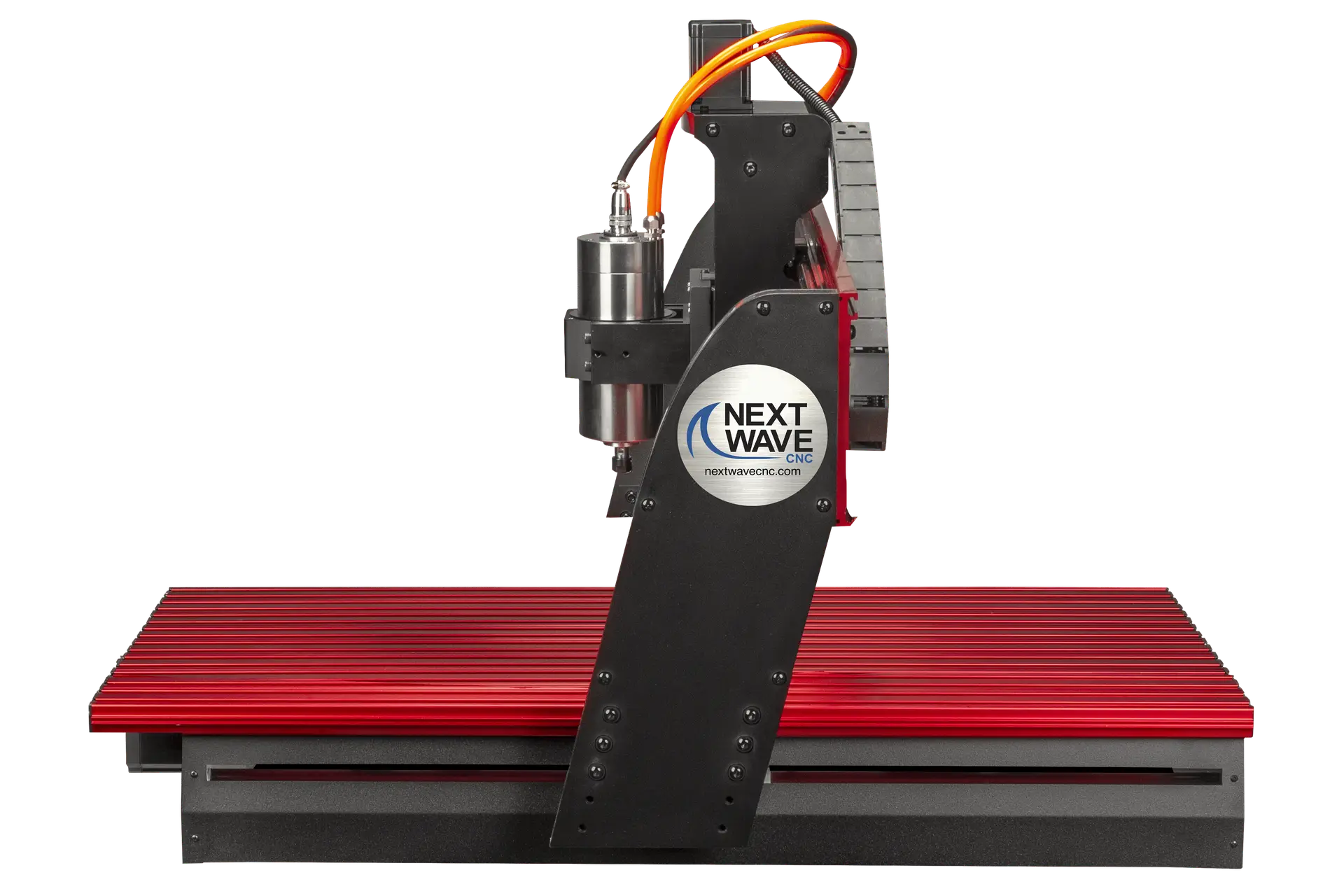

The Next Wave Shark HD500® has a cutting area of 13” X 25” X 7”. The SHARK HD500® will handle all your machining needs, whether it’s in a home shop environment or on the production floor.

Next Wave CNC’s SHARK HD500® comes standard with everything you need to quickly get set up and running: the latest version of Vectric VCarve Desktop design software, a color pendant controller, 2 hold-down clamps, carbide V-bit, Next Wave Ready2Control Software, and Next Wave CNC’s exclusive, patented Virtual Zero Unlimited software.

The Shark HD500® features a 16” x 36” table with an extruded aluminum router mount for 3.5” barrel routers (or any Next Wave CNC spindle system) and robust linear gantry rails.

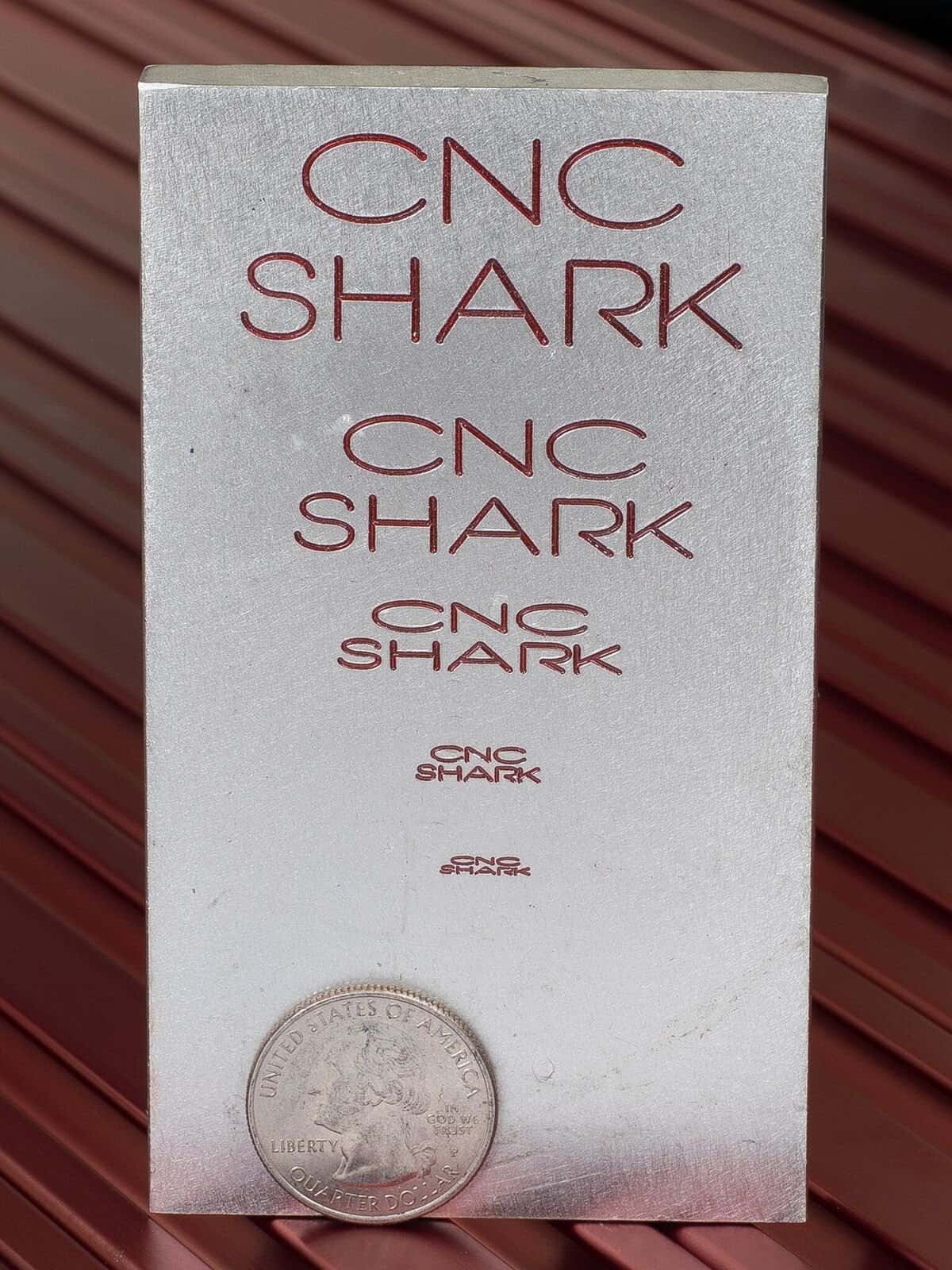

The HD500® can be pendant or computer-controlled and perfect for projects such as carving plaques, signs, ornamental boxes, and precision parts machined from wood, soft metals, or plastics. Enhance your woodworking capabilities with this versatile machine. This CNC router offers 3D carving capability with a 3D model library included. You can cut beautiful relief carvings, intricate inlays, and create exquisitely detailed engravings with ease.

The Shark HD500® creative potential is endless. Beginners to professionals are incorporating this diverse woodworking tool for custom parts, joinery, precision drilling functions, or all things decorative.

The Shark HD500® offers two control options:

- Using the included Vectric VCarve Desktop Design Software, you create your project and transfer it to a USB drive which plugs directly into the LCD pendant. The convenient touch screen Pendant interface eliminates the need for a computer controlling the CNC in your shop.

- For more control interactivity you can run the Shark HD500® from your computer with the Ready2Control program. This lets you use the exclusive patented Virtual Zero Unlimited® program. Our program will adjust your design to fit curves and angles that would be impossible on other brands of machines. (Computer and flash drive not included).

The Shark HD500 ® is the perfect tool for carving or machining a large variety of projects made from wood, soft metals, composites, or plastics. It is fully compatible with Next Wave CNC’s extensive product line of additional accessories, such as a spindle, laser, 4th axis, digital probe and drawing tool.

The Shark HD500® is made in the USA and includes USA Based Technical Support for the Original Owner.

Specifications:

- Table dimensions: 16” x 36″

- XYZ travel: 13” x 25” x 7”

- Overall dimensions: 24-1/4”W x 36”L x 24-1/2”H

- Interlocking slotted rigid aluminum table allows virtually unlimited clamp positioning

- Color Touch Screen pendant controller system

- Router on/off is controlled by the software and machine controller.

- Built with industrial-grade components, the SHARK HD500® also features a heavy-duty aluminum and steel reinforced gantry, a new extruded aluminum router mount system, interlocking aluminum table, linear rails, and guides on the gantry, and anti-backlash, wear-compensated lead screws on all axis.

- Built to handle larger 2.25 HP routers with 3.5” barrel diameter like DeWalt 610, 616, 618, PC 890 Series, Bosch 1617 or 1618 (router sold separately)

Included:

- The latest edition of Vectric Vcarve Desktop design software $349 Value now incorporating Cut 3D functionality and Vector Art 3D Sampler Pack

- Ready2Control Software– to control your machine with a PC if desired. Also, Virtual Zero Unlimited, $149 value, this patented Next Wave exclusive software allows you to map the surface of your material by taking an unlimited number of reference points. The program then uses these points to auto-adjust the G-code to conform to the actual surface of your material. This eliminates problems caused by a warped or bowed work piece and allows you to maintain a constant cutting depth on projects that other machines would not be able to handle.(Requires a PC computer with USB 2.0 port (not included))

- 2 hold down clamps

- Carbide V Bit

- Made in USA

- 2 Year Warranty

- USA Based Technical Support

Expand Your Capabilities with Accessories

Take your projects to the next level with optional add-ons:

- 4th Axis for rotary carving – – CLICK HERE

- Laser module for engraving – – CLICK HERE

- Digital probe for duplicating 3D items – – CLICK HERE

- Drawing tool for unique artistic designs – – CLICK HERE

Click here to view HD500 Manual

Check out our videos to learn more about our Shark CNC machine. If you have specific questions about the Shark HD500 or one of our other products, call (419) 318-4822 or email support@nextwavecnc.com to get in touch with our support team.

SKU: 10032-BUNDLE

UPC: 853211006749